Formula 1, the pinnacle of motorsport, is renowned for its cutting-edge technology, incredible speed, and, of course, the skill of the drivers. In this comprehensive exploration, we delve into the history of this beloved sport, the engineering marvels that propel F1 into a league of its own, and the magic machinery that helps it soar.

A Brief History of F1

Established in 1950 as a global championship competition, Formula 1 held its inaugural race at the Silverstone Circuit, a former Royal Air Force station in the United Kingdom, on May 13 of that year. The Formula 1 races generally last between an hour-and-a-half and two hours, however this may alter from time to time. Every race on the calendar is assigned a specific number of laps determined by the length of its corresponding circuit. The race distance typically corresponds to the fewest number of laps required to surpass 305 kilometres.

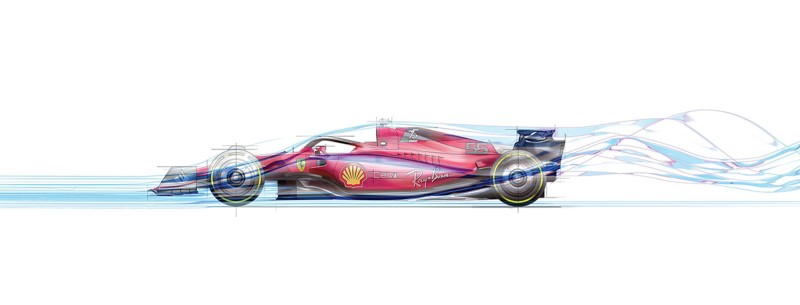

The creation of some of the swiftest and most technologically advanced racing cars on Earth involves thousands of components. These encompass intricate bodywork, suspension elements, turbo-hybrid power units, eight-speed paddle-shift gearboxes, 18-inch tires, and an array of other sophisticated parts. Throughout the years, wee have seen some of the automotive industries greatest technological advancements highlighted on the F1 stage. When the engine roars to life, an F1 car essentially functions like an airplane inverted, featuring front and rear wings, along with everything in between. These components work in unison to press the car onto the track, providing extraordinary levels of grip as it manoeuvres through corners.

Aerodynamics: Slicing Through the Air

The sleek and aerodynamic design of F1 cars is not just for aesthetics; it’s a fundamental necessity. Aerodynamics plays a pivotal role in ensuring maximum speed, stability, and efficient fuel consumption. We explore the science of downforce, drag reduction systems, and the constant battle teams face to find the right balance between speed and stability.

The design and engineering principles governing these cars have undergone significant transformations throughout the sport’s history, mirroring the rapid pace of innovation. In the preceding era of F1 (2017-2021), the cars reached unprecedented speeds, setting new records for velocity. For example, The peak speed of an F1 race cars is around 233 mph. Additionally, McLaren and Lando Norris secured the DHL Fastest Pit Stop Award in Qatar and set new records by executing a lightning-fast tyre change in just 1.80 seconds.

Nevertheless, this extraordinary speed came with a drawback. A major issue plaguing this generation of cars was their instability when trailing a competitor. The culprit was identified as “dirty air,” referring to the turbulent wake created by the leading vehicle. The consequence was a substantial decrease in grip, presenting a formidable challenge for drivers when attempting to follow, and consequently, engage in competitive racing. The FIA has outlined a strategy to adjust Formula 1’s technical regulations in 2025 as a precursor to the significant rule overhaul planned for the subsequent year, aimed at addressing the issue of turbulent air affecting the cars.

The Materials and Manufacturing Behind The Magic and The Pursuit of Lightness and Strength

Weight is the enemy in F1, and teams are in a perpetual quest to shed every unnecessary gram. Carbon fiber, with its unique combination of lightness and strength, is the material of choice for constructing the chassis and many other components.

The F1 cars are propelled by turbocharged V6 engines with a staggering 15,000 RPM, incorporating kinetic and thermal energy recovery systems.

Tires are the only point of contact between an F1 car and the track, making them a critical factor in performance. The Italian manufacturer, Pirelli, reentered Formula 1 in 2011, marking a comeback after previous involvements in the 1950s, ’80s, and ’90s. For the 2022 season, Pirelli engineered all-new 18-inch tires, aligning with comprehensive changes in technical regulations.

This overhaul encompassed a ground-up redesign, spanning the tire profile, structure, and the formulation of various compounds. Pirelli’s tire development process included an exhaustive phase of more than 10,000 hours of indoor testing, coupled with 5,000 hours of simulation. Additionally, they crafted 70 virtually developed prototypes, resulting in 30 distinct specifications. These specifications underwent rigorous testing by teams, covering a distance exceeding 20,000 kilometres.

Following a successful inaugural season under the reset rules of F1, Pirelli introduced some compound adjustments in 2023. These modifications were informed by tests conducted during practice sessions for the Mexico City and Sao Paulo Grands Prix in the previous year, along with additional testing in Abu Dhabi post-season.

Team Dynamics: The Human Element

While technology plays a monumental role, the human factor is equally vital. Formula 1 cars have consistently existed at the forefront of engineering excellence, with iconic figures like Ayrton Senna, Michael Schumacher, and Sir Lewis Hamilton becoming synonymous with these technical marvels. The coordination between drivers, engineers, strategists, and the entire pit crew can make or break a race. We delve into the intricate teamwork and decision-making processes that unfold behind the scenes during a Grand Prix.

The current F1 grid consists of 20 drivers distributed among 10 teams, each team fielding two cars. This encompasses long-standing F1 participants like Ferrari and McLaren, as well as more recent entrants like Haas, who joined the sport ahead of the 2016 season.

If your ambition is to pursue a career as a Formula 1 engineer, contributing to the development of the 2023 F1 cars and beyond, a foundational requirement is a degree in mechanical or automotive engineering. Proficiency in CAD packages and a comprehensive understanding of mechanical, electrical, hydraulic, thermodynamic, or pneumatic principles are essential components of the skill set.

However, even with stellar academic achievements, securing a position in the F1 paddock is not a guaranteed sprint. Similar to the competition for driver seats, the realm of Formula 1 engineering is an intensely competitive arena. To thrive at the pinnacle of motorsport, aspiring engineers must distinguish themselves even further. For graduates or undergraduates, a strategic approach involves cultivating employment opportunities through motorsport-related work experiences, whether through internships or volunteer work. After gaining valuable experience and earning a degree, many engineers initiate their careers in lower-level motorsport roles. This often entails roles such as data engineers or general engineers in the lower Formula and various single-seater racing categories.

However, even at this stage, a spot in a top-tier team is far from assured. Prominent constructors like Mercedes, Red Bull, Ferrari, and McLaren typically run their graduate programs, meticulously selecting the brightest minds to join their teams. For those aspiring to work in the thrilling paddock environment, globetrotting with the crew, the journey may commence by working in one of the team’s factories. Here, tasks range from conducting vital research and contributing to the development of championship-winning cars to working on intricate aspects like tire-degradation modelling, which significantly influences race strategies.

To conclude, Formula 1 is a mesmerising symphony of technology, speed, and human expertise. From the roar of the engines to the precision of aerodynamics, every element works in harmony to create a spectacle that captivates millions around the globe. In this exploration, we’ve peeled back the layers to reveal the fascinating stories of innovation that drive the cars—and the sport—forward.